multifid

design and prototyping of the panel system

The key points on which the project was based were the following:

- junction of the different layers of recycled corrugated cardboard derived from the industrial activity of the co-proposer;

- creation of a modular system that satisfies the need for versatility of use, adaptability and reversibility;

- quickness of production and industrialisation;

- ease of transport and assembly;

- fulfilment of the thermo-hygrometric performance of the panel to be used as an insulating layer;

- integrability of the sensory system.

The concept around which the idea revolves is that the panels are characterised by the assembly of gluing sheets of corrugated cardboard. The highlight of the system is in its simplicity because thanks to the addition or subtraction of layers, it will be possible to increase or decrease the thickness of the panels, adapting them to the needs of the Intelligent Factory.

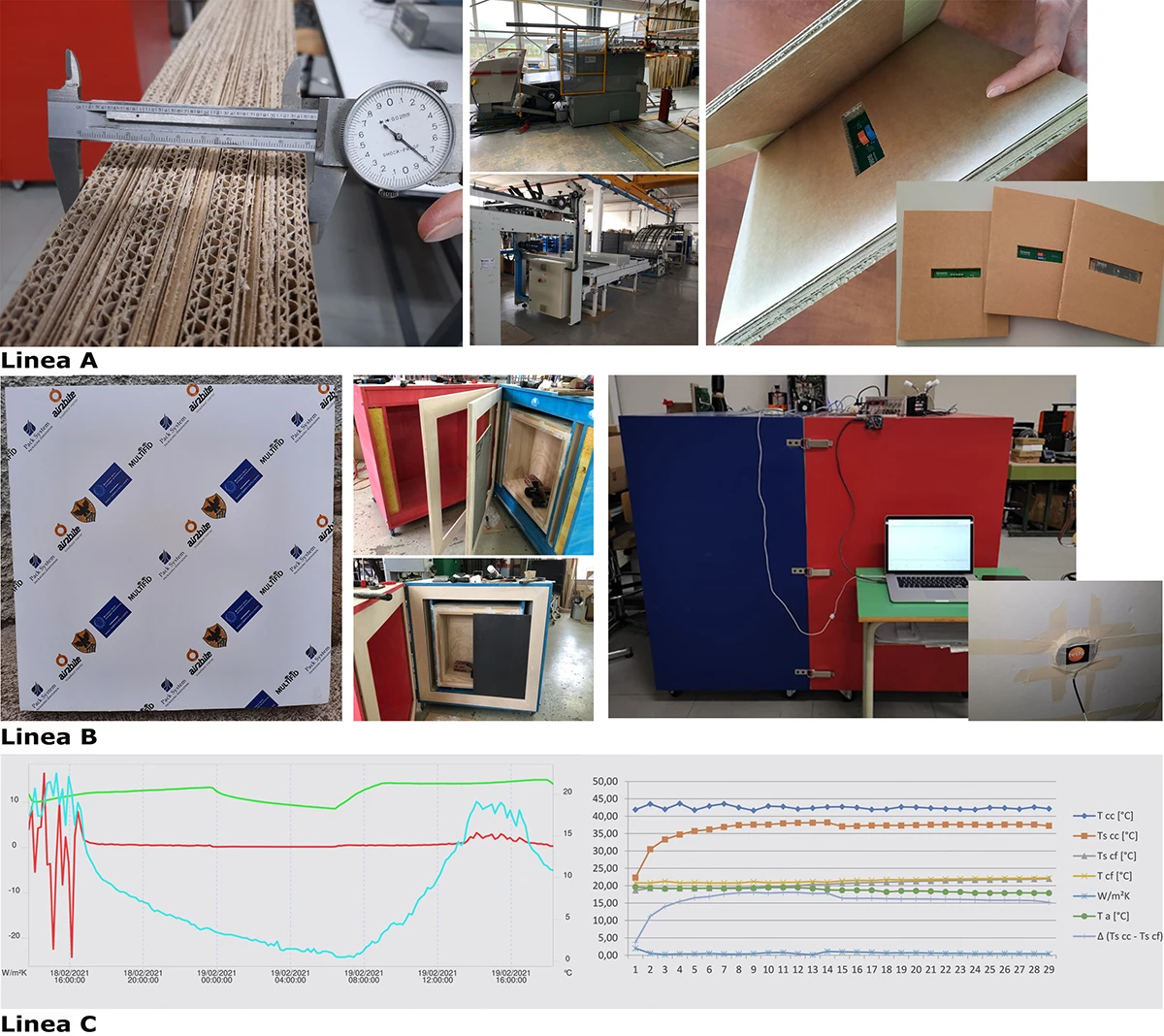

The layers were placed according to three different orientations: parallel, orthogonal 1x1 and orthogonal 2x2. The panel incorporates internal slots to case the sensorial architecture. As regards the finishing, it was expected that the panel has a fire protection treatment through paints already on the market and a completion layer created with printing on the cardboard. This finishing was preferred to other compatible typologies because, after some tests, it was found to be the one that least affected the signal of the sensory system.

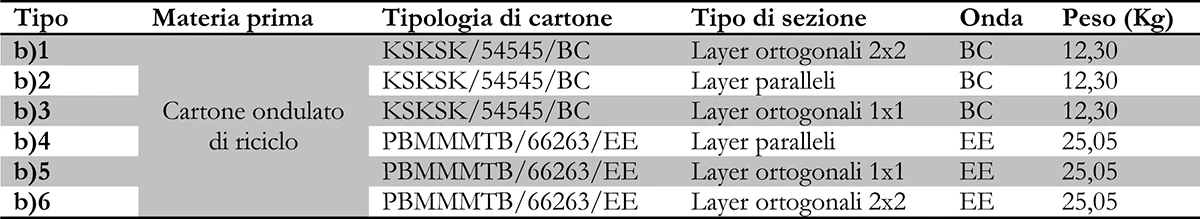

The main typologies of recycled cardboard at the disposal of the co-proposer used for the development of the Panel System were the following:

- KSKSK/54545/BC;

- PBMMMTB/66263/EE.

Starting from this material, six different types of panel prototypes were designed (Tab. 1; Fig. 2).

Tab 01 |

Riepilogo dei principali dati tecnici dei sei prototipi progettati

(graphic processing by M. Rotilio)

(graphic processing by M. Rotilio)

Figura 02 |

Due delle sei tipologie di prototipi progettati

(graphic processing by M. Rotilio)

(graphic processing by M. Rotilio)

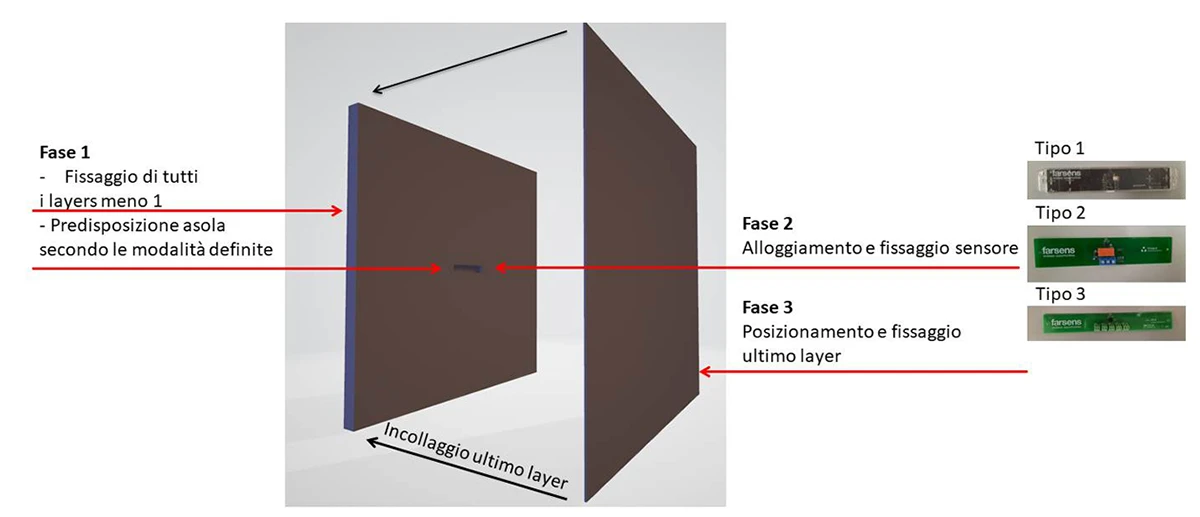

From the perspective of the integration of RFID sensors, a slot was designed within the modular system taking into account three main elements:

- the geometry of the sensors;

- the position of the casing containing the sensor in the panel thickness;

- the integration and connection between the sensor and the panel.

In terms of the first point, three different slot typologies were designed because the sensors to be used have three different geometries. In relation to the position of the casing containing the sensor in the thickness of the panel, different tests were carried out in order to understand which was the position that, among the ones hypothesised, least affected the communication between the elements of the sensory system. Due to its ability to ensure the best signal transmission, the slot was positioned towards the panel side in contact with the internal environment of the smart factory and, in particular, in the centre of this panel. The slot was designed in such a way as to be placed immediately before the last layer of corrugated cardboard in order to be completely hidden, to prevent the damage of the subsequent surface finishing of the panel and to protect the sensor from any manipulation or extraction by unauthorised personnel. Regarding the fixing between sensor and layers, a dry connection with metal screws was provided. This system is consolidated by the analysis of commercial cardboard products in addition to the fact that the three types of sensors are already equipped with slots to house the screws.

The assembly process involves three phases described in figure 3. Firstly, the individual layers will be glued with the exception of the last one, and the slot will be prepared according to the design indications. Subsequently, one of the three types of sensors will be housed and fixed and lastly, the remaining layer will be glued (Fig. 3).

Figura 03 |

Fasi inerenti l’integrazione pannello-sensori

(graphic processing by M. Rotilio)

(graphic processing by M. Rotilio)

The integration system designed and described is such that, in the event of a necessary replacement/control of the sensor, only the last layer of the panel would be sacrificed, recovering the sensor without difficulty, unlike some already patented systems that contemplate a sensor fixing through glues which, in case of removal, would cause damage and/or loss of the entire panel.

The design phase illustrated was conducted taking into account the machinery already supplied by the co-proposer, in order to guarantee the industrial manufacturing of the product; its final destination will be that of marketing. The production speed achieved is approximately ten minutes for the BC corrugated cardboard panel and fifteen minutes for the EE one. These times include the realisation of the slot and the housing of the RFID.

Different types of tests and laboratory trials were carried out on the prototypes to verify the achievement of the MULTIFId goals. Specifically, in addition to the calculation pursuant to UNI ISO 6946: 2008, analyses were carried out to verify the thermal conductivity of the panels thanks to the use of the Guarded Hot Box, designed ad hoc by the consultants, and heat flow tests with a heat flow metre. The results achieved prove that the conductivity values of type “B” panels oscillate between 0.044 W/mK and 0.064 W/mK, according to the type (Tab. 1). Therefore, they not only satisfy the project Kpi, but they are consistent with the lambda values of other construction products which are used for thermal insulation. Consequently, the designed panel system may be used in order to achieve thermal improvement of the factory envelope (Fig. 4).

Figura 04 |

Produzione dei pannelli e test. Linea A, alcuni dei prototipi prodotti e delle macchine industriali impiegate. Linea B, finitura superficiale del pannello, scatti inerenti le fasi di costruzione della Guarded Hot Box e di test. Linea C, output grafico rispettivamente di analisi termoflussimetrica (a sinistra), e Guarded Hot Box (a destra),

At the same time as the activities described, which are necessary for the definition of the so-called constructive system, the tasks to define the sensory system were carried out.

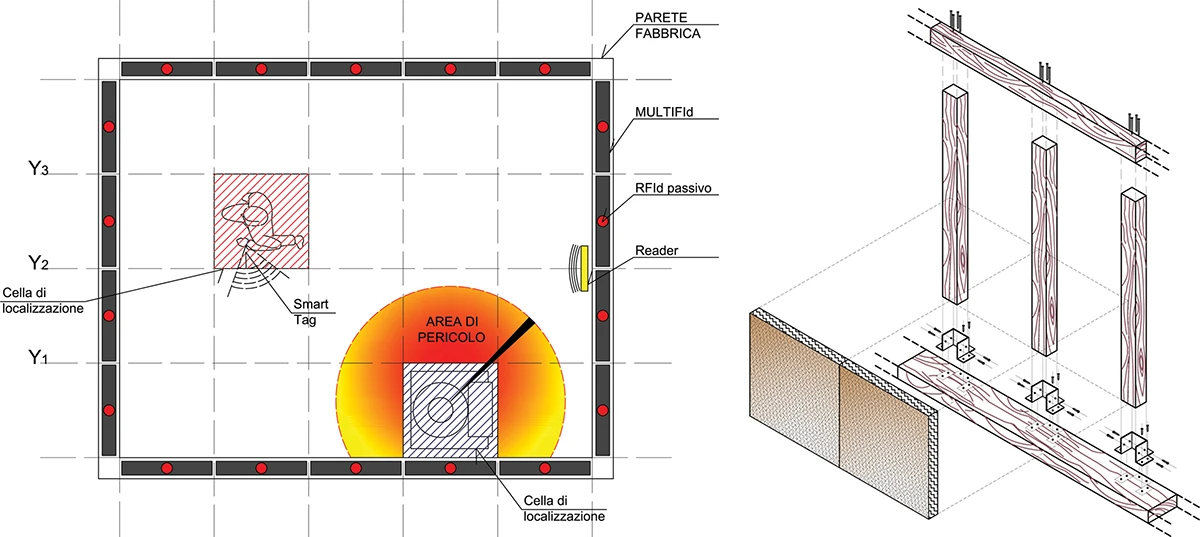

The MULTIFId architecture was designed with the aim of implementing safety in factories through the control of aspects such as the entry of workers into risk areas and man-machine and man-robot interaction. The panel position on the walls of the factory allows the partition of the internal volume into portions that can be uniquely identified through Cartesian coordinates. In this way, the position of each resource within the volume can always be known if it is equipped with a smart tag. This system may mitigate the risk in many dangerous conditions, such as in the case of an isolated worker in the hypothesis of a man-down recovery, or in the event that an unauthorised operator enters the risk area of a machine/robot. All these things may be managed remotely, through alerts, warnings and direct communications to the rescuers and to the corporate HPPS, Head of the Prevention and Protection Service. The designed system consists of a tag with chip and antenna, an additional antenna that communicates with tag one through radio waves, a reader that, on the one hand, exchanges data with RFID tags and, on the other, interfaces to a computer to which it is connected via an interface middleware. Moreover, the panel is equipped with humidity sensors for continuous monitoring. Similar to the construction system, the sensory system has also been the subject of many tests and laboratory trials to verify the correct signal transmission and efficient operation.

The last planned activity concerns the executive design of the panel fixing system and the design and construction of the “MULTIFId System” box (Fig. 5). This box reproduces the interior of an Intelligent Factory in a prototype version and will allow the system to be calibrated through tests and checks, identifying any subsequent issues and possible refinement and optimisation solutions.

Figura 05 |

A sinistra: schematizzazione del funzionamento del “Sistema MULTIFId”. A destra: dettaglio costruttivo del sistema di fissaggio dei pannelli

Thanks to the employment of recycled material and the optimisation process of the industrial production phase mentioned above, it has been estimated that the panel, suit of finishing, fire protection and equipping with a sensor will cost about 13-15 euros per square meter. This value is slightly lower than the average cost of the most popular construction products intended for thermal insulation which, however, are not multifunctional or intelligent due to the lack of the sensory system.

Figura 06 |

Test sistema sensoriale su prototipo realizzato in scala reale