multifid

prototype A

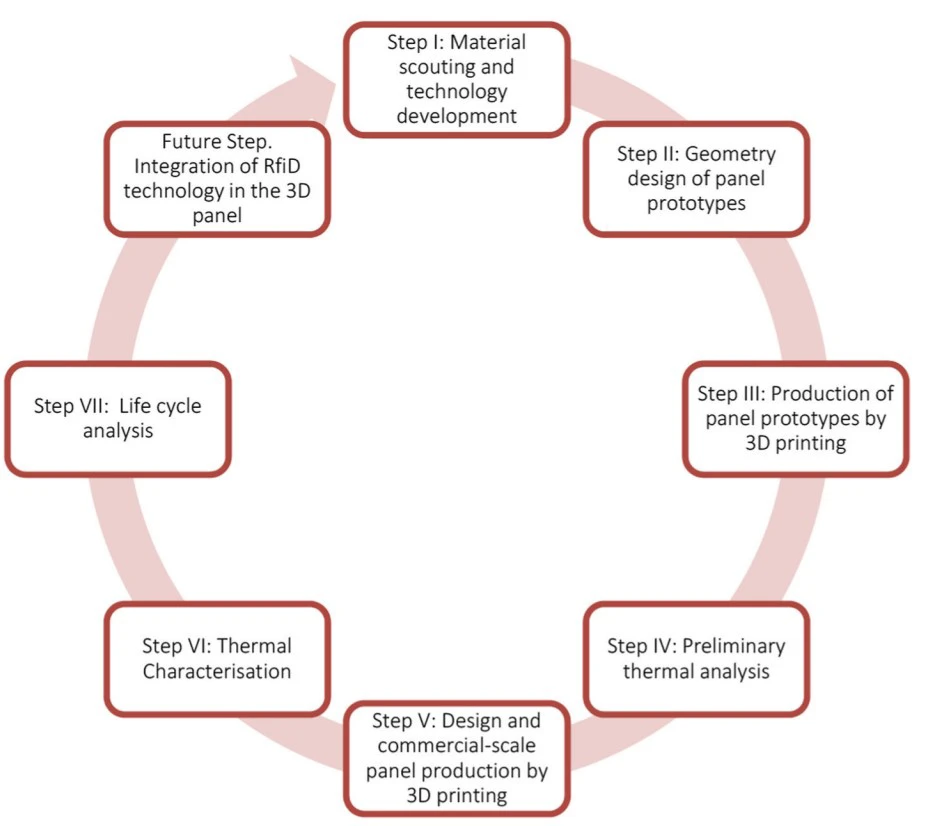

This panel is made with Hemp-Pla, where hemp comes from the residues of threshing leaves, and is printed with additive technology. The achievement of the final result has required the elaboration of six prototypes, differentiated from each other according to the geometry of the section, the thickness, and the infill. The development of several prototypes made it possible to identify the main printing difficulties and the time and amount of material required.

Open ‘Prototyping’ galleryFigura 07 |

(graphic processing by M. Rotilio)

(graphic processing by M. Rotilio)

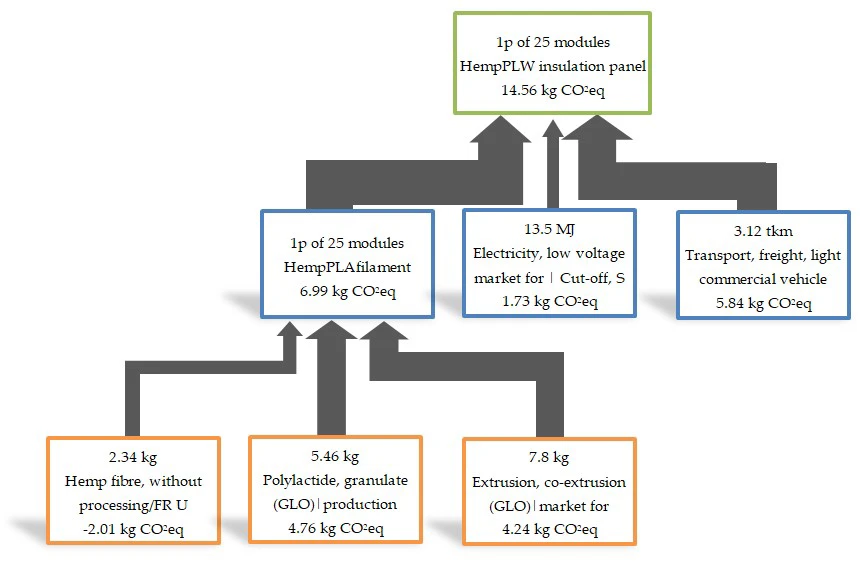

Based on the knowledge gained during the printing process of these prototypes and the analyses aimed at knowing their main thermal performance, it was possible to design and create a commercial-scale panel. Its energy performance values are comparable to panels already made from traditional materials. In addition, the Life Cycle Assessment showed that the results obtained are auspicious for bringing the printed panels made from Hemp-Pla to the construction industry market.

Open the ‘Final Panel’ galleryFigura 08 |

(graphic processing by M. Rotilio)

(graphic processing by M. Rotilio)

Summary of technical data for the six prototype types referring to panel type a)

| n. | Width (mm) | Length (mm) | Thickness (mm) | Infill (%) | Section type | Production speed (hours.minutes) | Quantity of material used (g) | Quantity of material used (m) |

|---|---|---|---|---|---|---|---|---|

| a)1 | 200 | 200 | 30 | 10% | Triangles | 6.33 | 235 | 29.22 |

| a)2 | 200 | 200 | 30 | 10% | Gyrod | 7.41 | 308 | 38.37 |

| a)3 | 200 | 200 | 30 | 10% | Cubic | 7.54 | 312 | 38.79 |

| a)4 | 200 | 200 | 50 | 10% | Tri-Hexagon | 10.37 | 436 | 54.26 |

| a)5 | 200 | 200 | 70 | 8% | Triangles | 11.40 | 482 | 60.01 |

| a)6 | 200 | 200 | 100 | 6% | Cubic | 11.38 | 445 | 55.31 |